Core Technological Competence

Core Technological Competence

The capability of R&D

Dailywell innovative product design thinking that meets customer expectations and delivers overall market success. Research various types of switch product structure, and this is one of the methods to strengthen its own product performance and technology upgrade. Use 3D printing to complete the rapid sample preparation service, and provide 3D files to facilitate communication with customers. Possesses a strong ability to incorporate win-win opportunities into the creative solutions to meet the needs of our various customers and business goals. Innovative product design thinking that meets customer expectations and delivers overall market success. Utilization of fundamental design principles with strong engineering aptitude. Strong contribution to overall product design projects from in inception to commercialization.

The capability of Tooling

Dailywell has established our own mold’s research and development center. The research and development of precise mold and operating technology fulfill the various specifications requirements of switches, the milling machine, the grinding machine, lathe machine, wire cutting machine and CNC lathe with automated product assembly line provide an integrated solution to capacity management.

The capability of Manufacturing

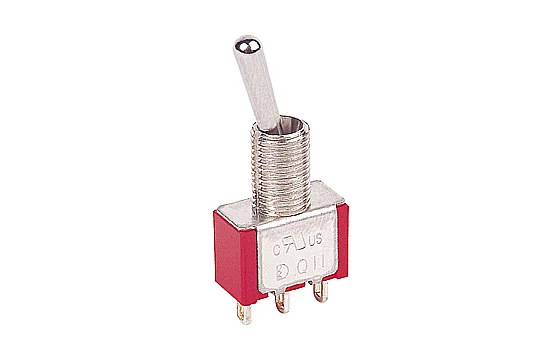

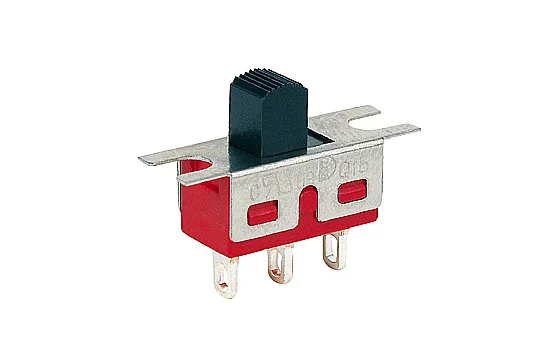

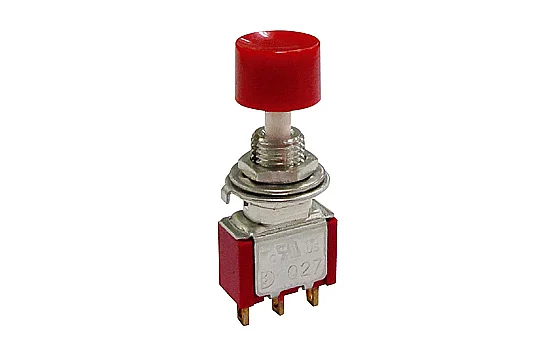

Our factory occupies an area of 15,000 m2 in Zhuhai, we focus on process technology and production efficiency constantly, and have not only consistent but also automated production line in control and management with annual capacity of 800 million pieces. We design and develop molding then produce various types of materials by our own. Including injection molding of plastic injection and manufacture metal components through press and lathes machine, robotic arm etc. A variety of raw material of processing plus our own supply production material, we could even operate under automation or manual assembly without time differences. The product lines' range from toggle switches to rocker switches and metal switches. There are 50 categories in total.

Core Technological Competence | Trusted Electromechanical Switch Manufacturer – DAILYWELL

As a specialized DAILYWELL switch manufacturer, we focus on metal, anti-vandal and panel switches engineered for demanding industrial, transportation and energy applications.

OEMs rely on DAILYWELL switches for stable electrical performance, robust mechanical life and IP-rated protection that helps equipment withstand vibration, dust and moisture in the field.

DAILYWELL integrates technology, production, quality systems and service into a unified structure that supports efficient operations and dependable results for partners worldwide.